Kanthal Palm Coast

From the 4/1/05 Newsletter

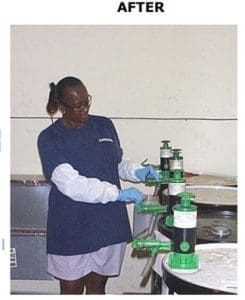

Almost from his first day on his job (as Chemical Mixer inEnameling), Bobby Tittle has questioned the way we dispense our coatings and solvents. Of course since ‘we’ve been in business 20 years and we’ve tried it all’ and ‘this is the best we can expect to do’, the standard answer to Bobby’s question was … ‘just keep on doing it the same way’ !

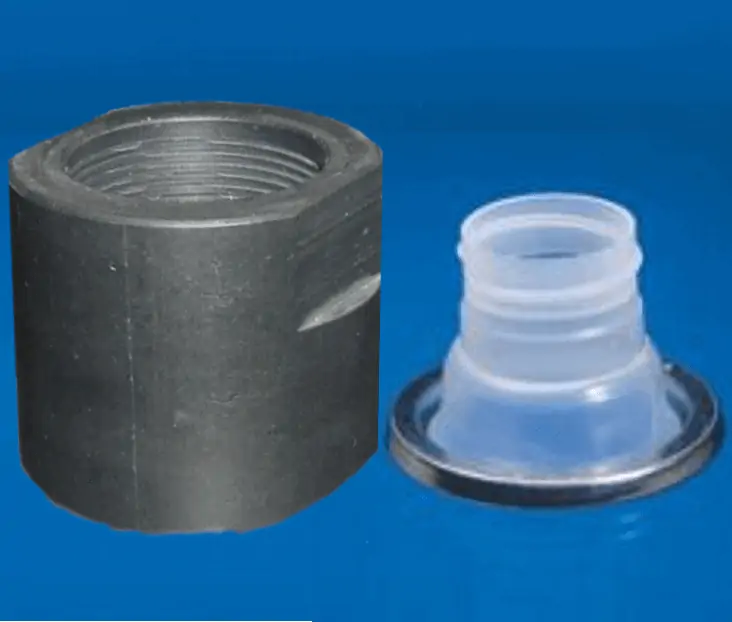

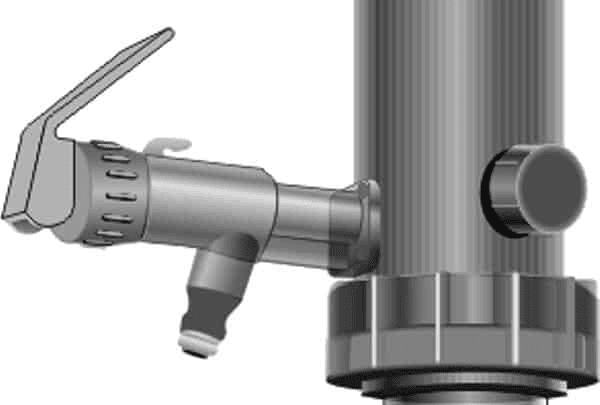

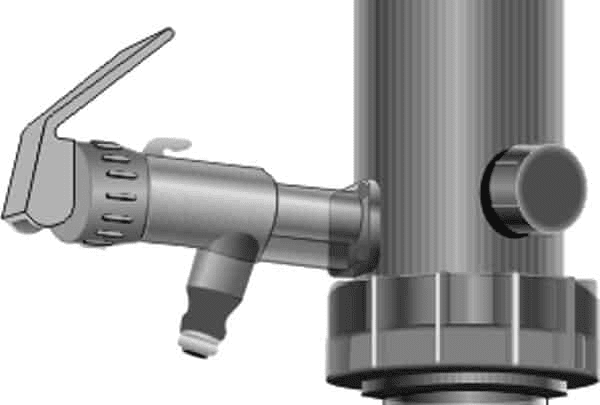

THEN – last November the GoatThroatTM pump appeared. A well-engineered, low-pressure plastic hand pump (basically a sophisticated siphon), the “goat” promised to “pump anything”. Well, it doesn’t pump everything – some of our coatings are too thick and heavy to pump easily. But after working for months with various combinations of pumps and seals (different chemicals require different seals for the “goat”) Bobby has our solvents and most of our bond and insulation coatings being dispensed by the “goat”.

So what’s new?

No more dripping brass and bronze valves, that lose valuable materials and create significant safety hazards Drums that can be dispensed sitting upright, rather than laying on their side; this saves space and the tough physical job of laying down drums that when full may weigh 500 lbs. (ask Gilbert how much fun loadingalcohol drums into a safety cabinet is!) No more 2-5 gallons of coatings – some of which cost $ 75 per gallon – left in an ‘empty’ drum; these not quite-empty drums cost about $30 to dispose of; a“clean” drum costs $7.

So what is new?

The improved margin of safety, less smell, less clean up, no more paying our money for getting rid of leftover coatings (that we earlier paid even MORE money to buy !) – and in general, a better workplace in the chemical room.

According to the Plant Manager, Mr. Yu, “ GoatThroatpumps helped us improve our overall efficiency. By dispensing our chemicals from vertical drums, it has helped us clean up our dispensing area by eliminating drips and small leaks. Another advantage is the ability to pump most of our drums almost completely empty. This alone saves us several thousands of dollars per month in disposal costs and chemical purchases.”

Download The PDF of this Article HERE

For the Original PDF and to See Other Case Studies, Click HERE