No More Tipping and Tapping

The San Joaquin, Calif., water and wastewater management facility is located on 100 acres. It serves 1.5 million people, processing 1.5 gallons per day per person. Its wastewater treatment plant sits on 20 acres, where weeds grow along the perimeter. To keep growth at bay, staff members frequently applied Roundup®.

The plant manager purchased the chemical in large drums and installed regular handpumps to transfer the liquid into dispensing sprayers. This process was difficult and messy for employees and wasted chemicals due to spillage. Within a few uses, the chemicals corroded the transfer pumps, which then had to be discarded into the landfill and replaced several times a year. Already, the hand pumps were not a good fit for this application, and soon state regulators had developed new guidelines.

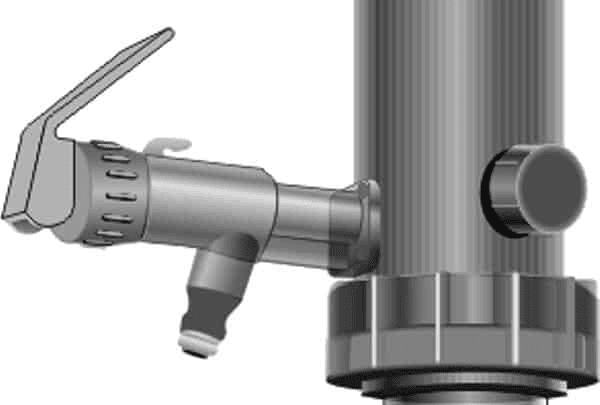

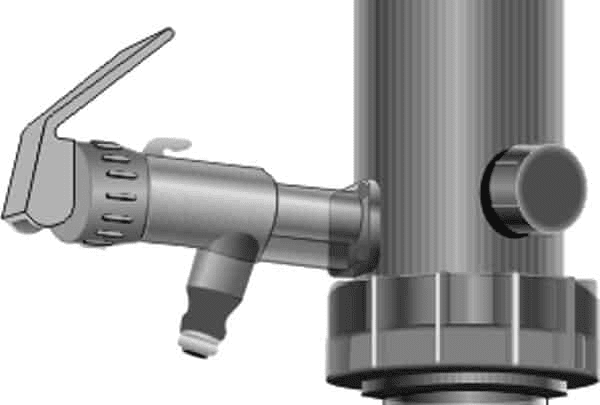

California Title 3 Pesticide Regulations Sec. 6742.3 (Safe Equipment) states that shut-off devices need to be installed on the exit end of all hoses carrying liquid pesticides in categories 1 and 2 to prevent splashes on employees and dripping when the filling operation is stopped. Sec. 6746 (Closed systems) requires connecting hoses, pipes, and couplings to remove a pesticide from its original container to guard against personal exposure.

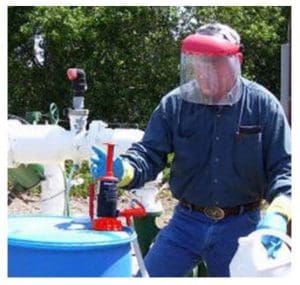

Early in 2006, the plant manager knew he had to find a better solution. His research led him to a GoatThroathand pump that pressurizes the drum and, through a remote discharge tap with a finger-tipped controlled shutoff valve and 5 feet of flexible tubing, dispensed the Roundup® to the dispenser sprayer with no splashing.

That was 4 years ago, and the staff is not only still using that original pump for Roundup®, but management replaced pumps in six other chemical applications, including caustic soda used for cleaning bio-growth from diffuser blades and for d-limonene and petroleum-based degreasers.

“When you find something that works that well and saves you money, you immediately want to use it anywhere you can. The great thing is that the pumps allow staff to transfer fluids efficiently from upright 55-gallon drums. No more dangerous tipping and tapping,” the plant manager said.

Download The PDF of this Article HERE

For the Original PDF and to See Other Case Studies, Click HERE