When a North Carolina biopharmaceutical company’s productivity was limited by the state fire code’s “Open Use” restrictions, the company’s Environmental Safety Department found itself facing chemical storage challenges at a new level.

Engaged in the design, discovery and development of NNR Therapeuticas, a new class of drugs for the treatment of multiple diseases and disorders of the central nervous system, the biopharmaceutical company used chemicals and solvents such as ether, methylene chloride, chloroform, hexane, ethyl acetate, isopropyl alcohol, methanol and toluene in its process. The company’s productivity problem stemmed from fire codes specifying that five-gallon containers of these types of fluids had to be stored on the first floor of their facility, when actually the solvents were needed in the lab on the fourth floor.

Safety is Compromised

The complicated logistics were dictated by restrictions in the fire codes, which limit the storage and use of certain chemicals in multi-level buildings, in order to minimize the potential fire hazards. The codes stipulate that the higher up in the building, the fewer “open-use” containers are allowed, as fumes (VOCs) from high vapor pressure and flammable liquids are fire hazards due to their increased potential for static ignition. In addition, “open-use” allowed excessive VOCs that posed a safety threat. In order to have the fluids handy on the fourth floor for the lab technicians’ immediate use, the company was facing the possibility of using one-gallon bottles of each of the fluids instead of the more cost-effective five gallon containers.

North Carolina’s fire codes define an “open-system” or “open-use” situation as: “The use of a solid or liquid hazardous material involving a vessel or system that is continuously open to the atmosphere during normal operations, and where vapors are liberated or the product is exposed to the atmosphere during normal operations.” Also, the code defines non-compliant, open situations as “…situations where hazardous solids or liquids are being dispensed from or into open beakers or containers,” making the process at this North Carolina company a prime example.

Based on the facility’s layout, the codes dictate that only containers up to one gallon in size are allowed to be open or stored above the first floor. The situation presented a tough choice for the facility: Continue the time-consuming practice of dispensing chemicals from large containers into smaller ones, and then transporting containers of fluids from the ground floor to the fourth floor; or take on the increased cost of purchasing solvents in smaller-quantity containers so that they could be stored near their point of use in the fourth-floor lab. But, according to the Environmental Safety Department, the answer to the challenge was to eliminate the open use situation, which would then allow the fluids to be housed on the fourth floor within larger containers.

An Open and Closed Case

However, the metal pumps the company had already tried on the ground floor were not the solution. Every pump they had tested perpetuated the open-use situation, allowing VOCs to escape into the air. Additionally, each one leaked, effectively spewing chemicals onto lab personnel. To make matters worse, because the pumps lacked a stop-flow mechanism, it was easy to overflow the receiving containers, which created a spill hazard. Regardless of the type, none of pumps could comply with the directive of a closed-use situation.

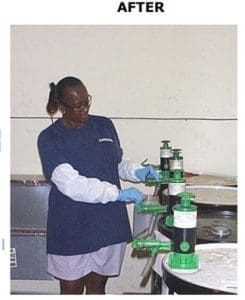

Convinced that there had to be a better way, one of the management’s staff members searched online for a solution, finding GoatThroat pumps. Designed to keep vessels closed, dangerous vapors are sealed within the container during normal operations, except when dispensing fluids, thus satisfying the state’s closed-use requirement. The department also was surprised to find that the pumps could be outfitted for compatibility with more than 700 chemicals, including methylene chloride, which in past tests had quickly compromised the effectiveness of other pumps they had tried.

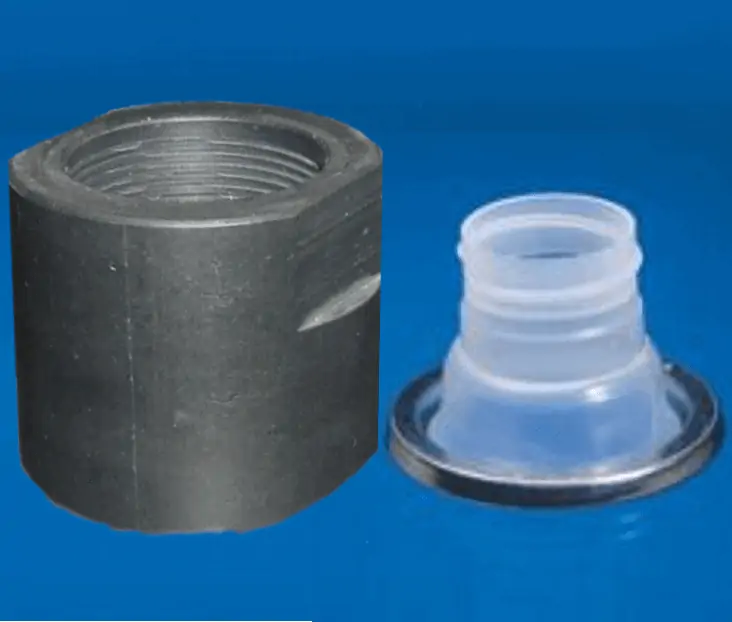

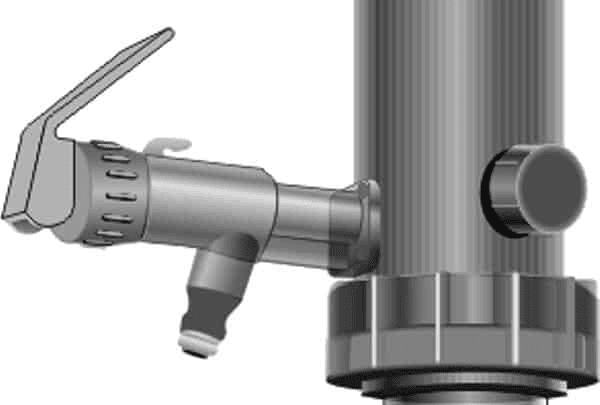

With fittings compatible with the Rieke Flex Spouts already located the five-gallon chemical containers, it is now possible for research technicians to safely dispense liquids without having to tip the vessels. Depending on the solvent’s viscosity, pumps deliver a steady stream of fluid up to 4 gpm at a low pressure of 4 to 6 psi. A drip-proof faucet has a spring-actuated on-off valve, allowing solvents to be dispensed with control from the safety cabinet into small beakers ready for use, thereby eliminating spills and leaking.

Conclusion

The new pumps have solved the company’s open-use situation. Now, except for the 55-gallon drum of toluene, which is also dispensed using one of the pressure pumps, all of the necessary solvent containers can be housed on the fourth floor near the lab technicians.

Not only did the pumps solve the logistical situation, they saved the employees time and the company money. Paying for themselves in less than two months, the pumps also provided cost-savings realized when the company was able to purchase solvents in large-quantity containers. After two years, the original pumps are still in use. Dangerous VOCs and odors are greatly reduced, and workers are protected and breathing safely, effectively impressing the Fire Marshall at last inspection.

For more information, contact Nancy Westcott at nwestcott@goatthroat.com or by phone at 646-486-3636.

AT A GLANCE

The company’s productivity problem stemmed from fire codes specifying that five-gallon containers of these types of fluids had to be stored on the first floor of their facility “Open-use” allowed excessive VOCs that posed a safety threat. The answer to the challenge was to eliminate the open-use situation, which would then allow the fluids to be housed on the fourth floor within larger containers.

Every pump they had tested perpetuated the open-use situation, allowing VOCs to escape into the air