Both Efficiency AND Safety – Not Either/Or!

If you’re relying on outdated gravity-fed methods to transfer fluids, then there’s a good chance you’re either risking the safety of employees to get every last drop, or you’re wasting precious product to keep from spilling chemicals and injuring the user. That’s the bad news, but there’s good news, too: it doesn’t have to be like that!

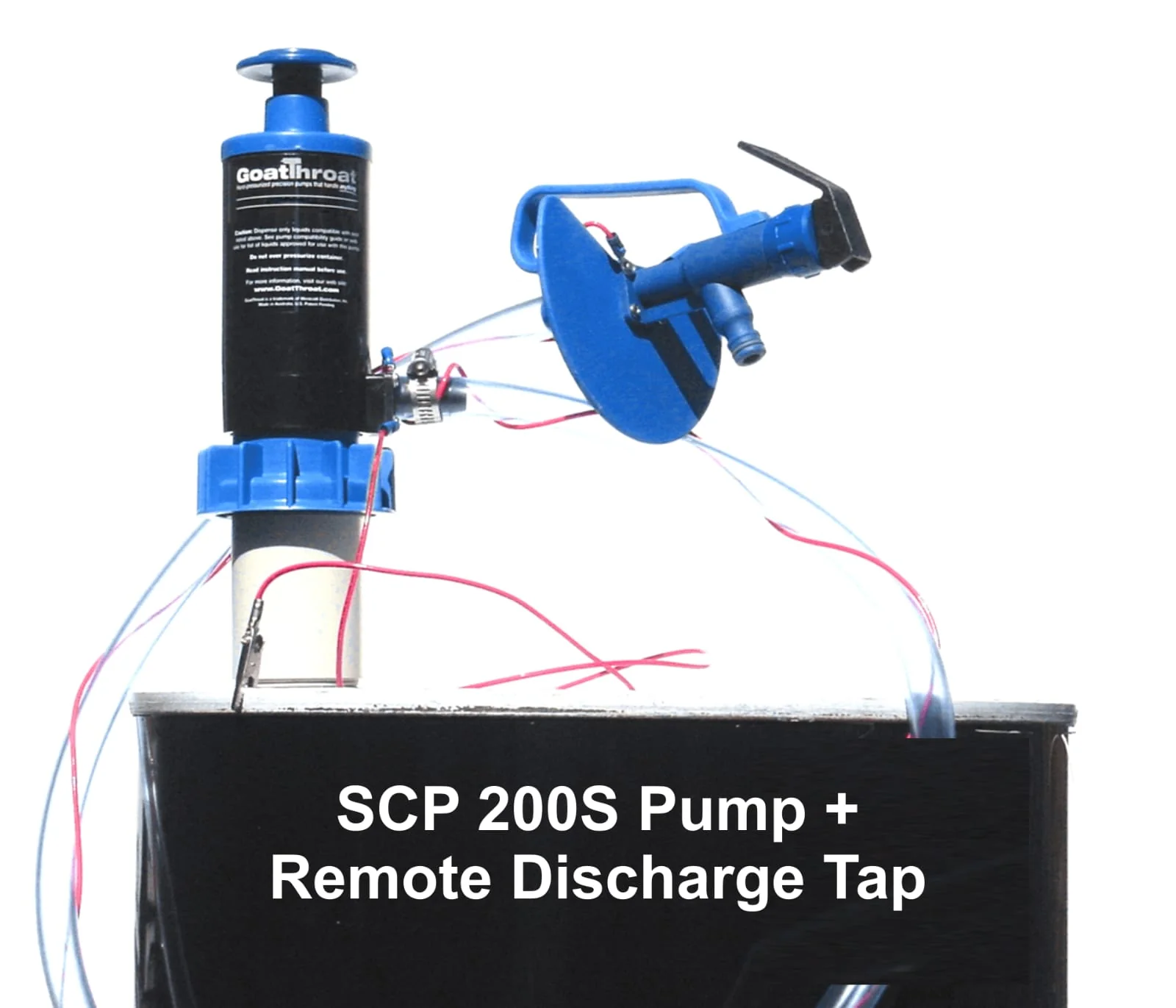

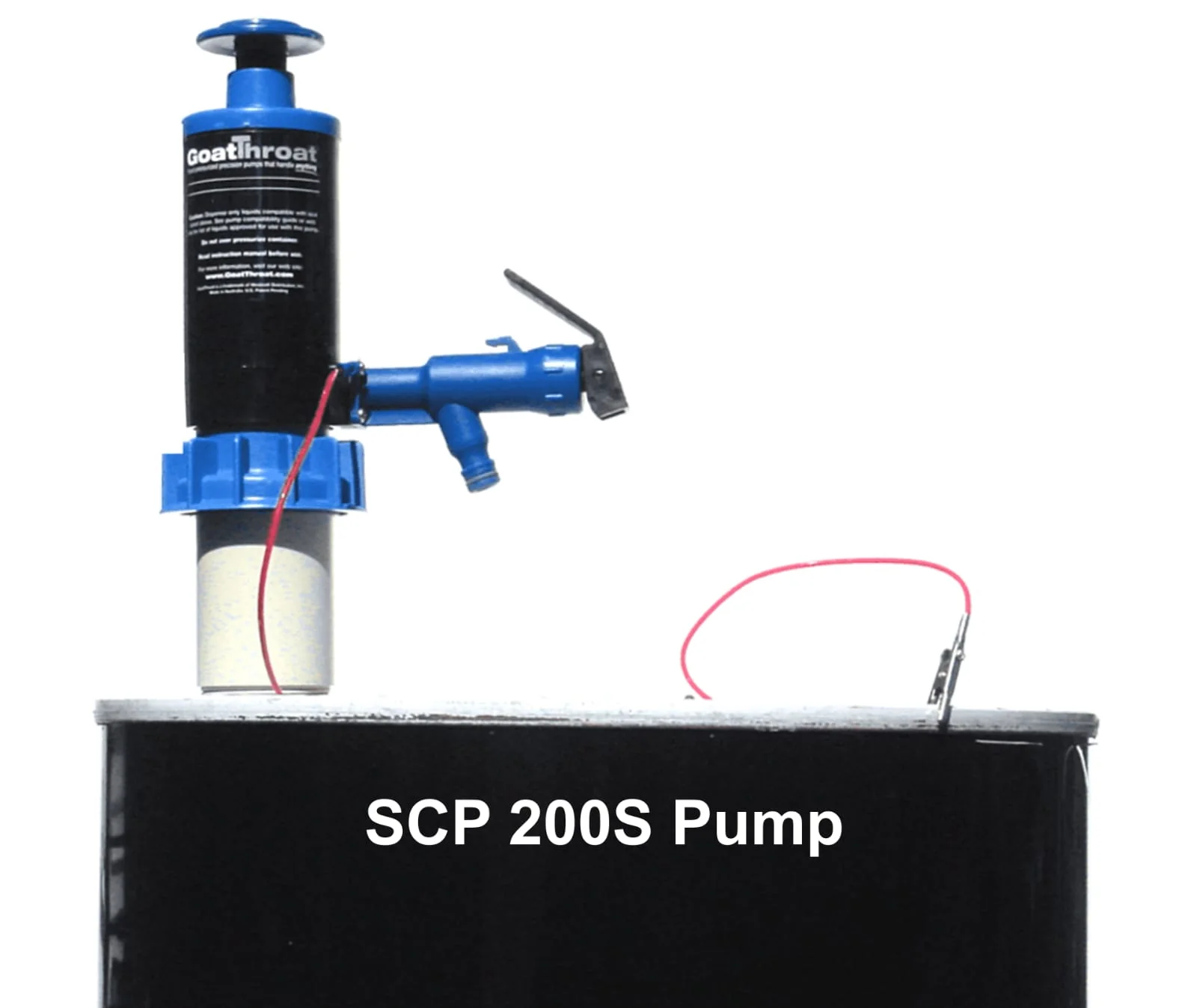

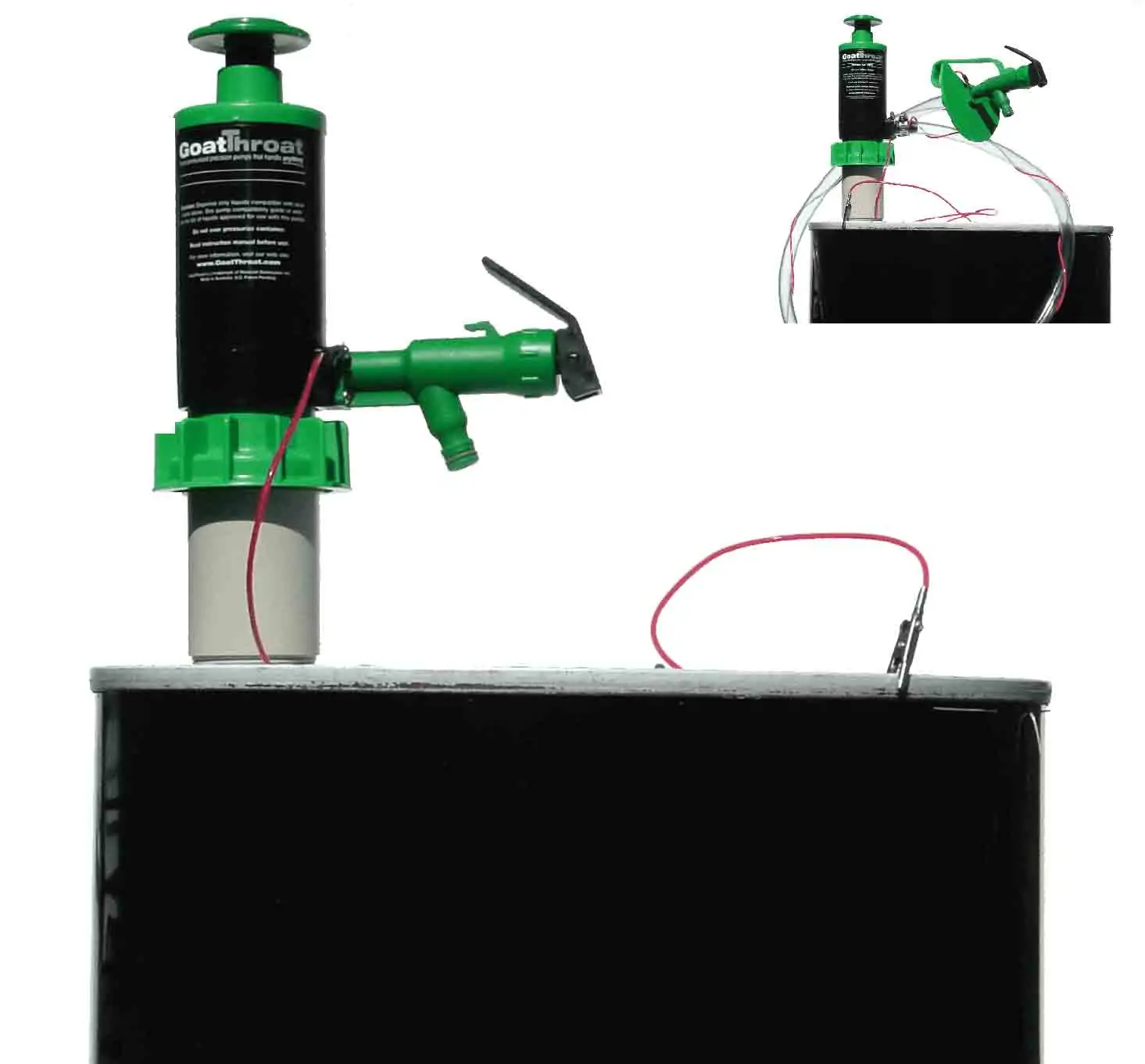

Gone are the days of sacrificing pricey chemicals and other liquids to ensure safety and prevent spills. GoatThroat pumps offer the best in efficiency AND safety thanks to a unique, chemically-compatible design that allows for accurate dispensing of liquids with the touch of a button. And while you’re saving money by reducing waste and preventing injury, you’ll also be saving money on replacing equipment: GoatThroat pumps last 10+ years.

Solving Solvent Situations: A Case Study

Take our client Ridgeway Industries of Pennsylvania, for example. Before they discovered GoatThroat chemical pumps, their manufacturing process involved tipping full 55-gallon drums of chemical-based cleaning solutions into a horizontal position for dispensing to point of use. This awkward, dangerous and labor intensive maneuver was highly susceptible to leaks and made it difficult to control the flow rate. Disaster to employees, the environment and the company’s bottom line was imminent.

Enter GoatThroat pumps. Ridgeway was able to reconfigure their entire process with a simple system that could safely dispense multiple cleaning chemicals from their individual drums without any dangerous tipping. The drums are able to remain upright while a single shop air-line, set at 4psi, runs the GoatThroat pumps attached to the top of the drum. With a single touch, employees can now safely dispense chemicals down to the last drop, which has the added benefit of adhering to the Resource Conservation and Recovery Act (RCRA) standard.

Zero-Waste, Zero Complaints: Configure Your Chemical Pump System

Prepared to perfect your pumping process? Use our Configure Your Pump tool to find the ideal solution for your unique chemical pump needs.